PVDF (Polyvinylidene Fluoride) Pumps

As a distributor, Coron Enterprise is committed to providing seamless access to Fluorolined Equipment Pvt. Ltd.‘s high-quality products, ensuring industries across India receive reliable solutions for their operational needs.

Fluorolined Equipment Pvt. Ltd. is a leading manufacturer of centrifugal chemical process pumps, utilizing specialized fluoropolymers, specifically PVDF (polyvinylidene fluoride), for handling a variety of corrosive liquids. For the past two decades, the company has been a trusted supplier to nearly 80% of the Indian steel and chemical industries.

PVDF (polyvinylidene difluoride) pumps, offered by Coron Enterprise, are engineered for handling highly corrosive and abrasive fluids. Known for their excellent chemical resistance, high purity, and superior mechanical strength, PVDF-lined pumps are ideal for critical applications in the chemical, pharmaceutical, and steel industries.

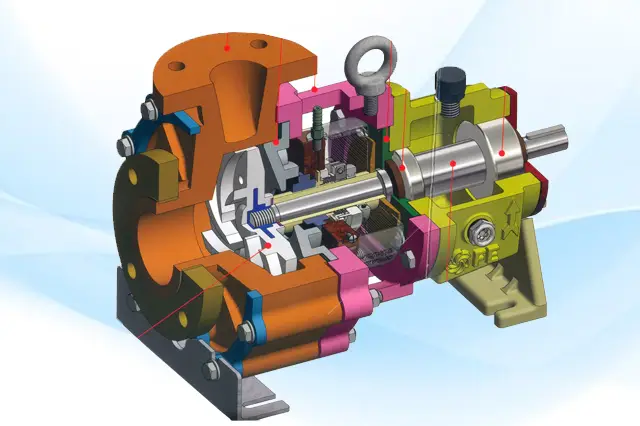

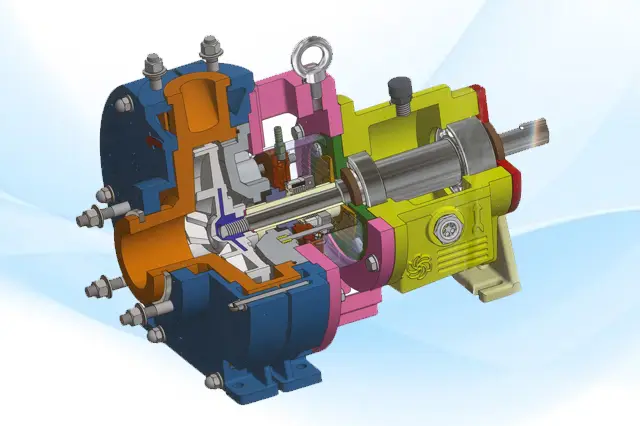

The casing liner and backplate are made from thick-walled polyvinylidene fluoride (PVDF), with the casing liner encased in a standard cast iron shell for enhanced durability. Both the casing liner and backplate are solid injection-molded at our manufacturing facility in Valsad.

The pump features a semi-open impeller, incorporating a large metal insert within the PVDF material. This significantly enhances mechanical strength and ensures an extended service life.

The bearing pedestal is equipped with a rigid shaft made from high-strength stainless steel (available in EN-8, EN-19, EN-24, or EN-41 grades), along with a double-row ball bearing designed for exceptionally high load capacity.

To provide better sealing, there is a special gasket made of polytetrafluoroethylene (PTFE) with a rubber insert, which helps to seal effectively.

Thanks to the robust cast iron armor surrounding the liner and the large metal impeller core, the PVDF used in Fluorolined Pumps can endure significant mechanical stress without becoming overloaded.

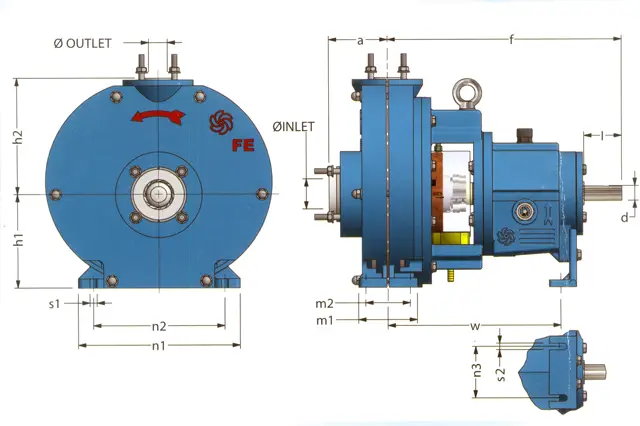

The back pull-out design enables simple maintenance, ensuring efficient servicing. Additionally, the pumps and base frames are externally protected from corrosion with a durable layer of epoxy paint.

Fluorolined pumps are available in 20 models, designed for maximum interchangeability. They are suitable for flow rates of up to 400 m³/hr, with a head capacity of 100 meters of liquid column.

Special Properties Of PVDF Pumps

- Excellent resistance to most chemicals and solvents

- High thermal stability—suitable for continuous operation up to 120°C

- Superior purity and mechanical strength, even at elevated temperatures

- Outstanding abrasion resistance and UV (sunlight) resistance

- List Item

- Resistant to nuclear radiation and fungal growth

- Low permeability to most gases and liquids

- Low flammability and minimal smoke generation