Polypropylene (PP) Pumps

Polypropylene (PP) pumps are extensively used in industries that demand corrosion-resistant and chemical-resistant fluid handling solutions.

Manufactured from polypropylene, a robust thermoplastic, these pumps offer excellent resistance to a wide range of acids, alkalis, and aggressive chemicals.

Ideal for chemical processing, wastewater treatment, electroplating, and acid transfer, PP pumps are well-suited for environments where metal components would be prone to corrosion. Their non-metallic construction ensures long-term durability and reliability even under harsh chemical exposure.

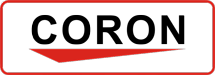

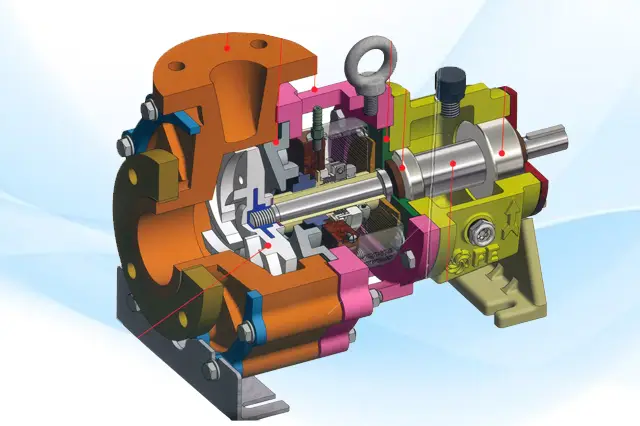

Most models feature a back pull-out design for simplified maintenance and semi-open impellers reinforced for improved mechanical strength and longer service life.

As a distributor of Fluorolined Equipment Pvt. Ltd., Coron Enterprise provides high-quality PP pumps backed by technical expertise and responsive customer support.

Features Of PP Pumps

- Low maintenance due to minimum components

- Low power consumption

- High Capacity

- Leak proof and also run dry without damage in rotating parts

- Enable effective solutions

- Controls Air Pollution

- Compact design

Applications Of PP Pumps

- Electroplating

- Fertilizers plants

- Paper and pulp industries

- Phosphoric acid plants

- HCL acid handling

- Pharmaceutical industries

- Corrosive liquid handling

- Dyes and pigment industries

- Thermal and atomic power plants

- Effluent treatment handling

- Scrubbing process

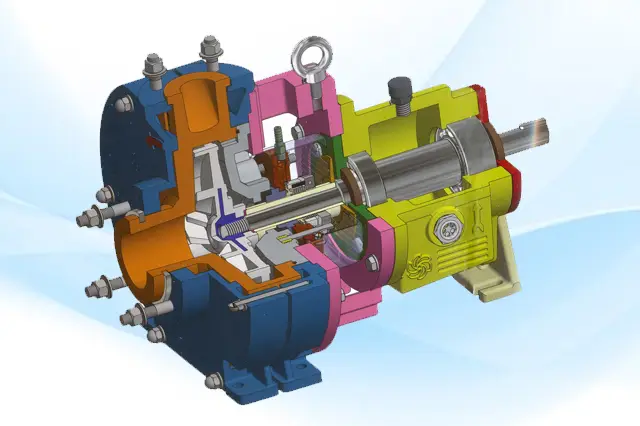

Technical Data

Operating Frequency | 50Hz | 60Hz |

Capacity [Q] up to | 500 m³/hr (2200 US gpm) | 3100 US gpm (700 m³/hr) |

Head [H] up to | 120 mts (394 ft) | 492 ft (150 mts) |

Motor Power [P] up to | 150 HP (115 kW) | 170 HP (130 kW) |

Viscosity up to | 150 mPas (cP) | |

Suction Lift up to | 8 m ( 26 ft ) with priming chamber * | |

Maximum Working Pressure | 12 bar (175 psi) | |

Maximum Specific Gravity [SG] | 1.8 – 3 | |

Minimum Continuous Flow | 3 m³/hr (13 US gpm) | |

Maximum Temperature | PP – H : 820C (1800F), GFRPP : 900C (1940F) | |

Suction & Delivery Connection | ANSI B16.5 – Class 150 , DIN ND 10 | |

Shaft Seal | Single (TB/TBR), DROTT, IMS, DMS & SS | |

Bearing | Rolling Element Bearing | |

Lubrication | Grease/Oil | |

Motor Compatibility | IS 1231, IEC 72 – 1, NEMA* | |