PFA / FEP Lined Pumps

PFA (perfluoroalkoxy) and FEP (fluorinated ethylene propylene)-lined pumps are designed to manage very corrosive, harmful, and pure liquids in tough industrial settings. These centrifugal pumps have a strong metal outer layer and are coated inside with PFA or FEP, which makes them very resistant to chemicals and helps them last longer.

Coron Enterprise, an authorized distributor of Fluorolined Equipment Pvt. Ltd., provides high-quality PFA/FEP-lined chemical process pumps to a wide range of industries, including pharmaceuticals, chemicals, semiconductors, and wastewater treatment.

Features

- Thick PFA / FEP Teflon moulded in place to ductile iron by high pressure moulding technique

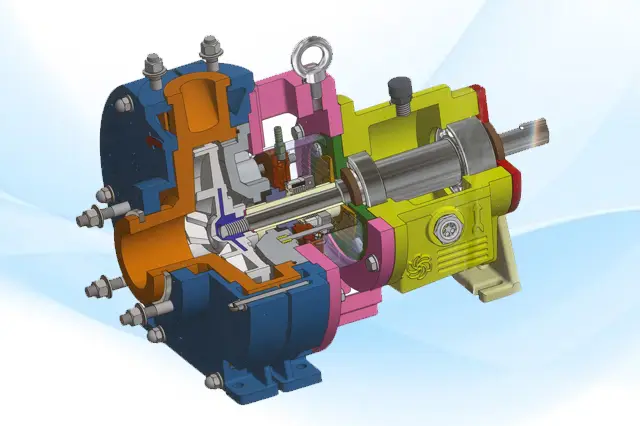

- Rigid frame (and casing) feet to reduce the effect of pipe loads on alignment

- Lubrications flexibility from oil to grease

- Heavy duty shaft and bearings designed for minimum deflection and for achieving longer life under tough operating conditions

- Shaft sealing to accommodate conventional seals, double seals, special seals without any water cooling

- Semi-open impeller acknowledged best design for chemical services - solids handling, stringy material, corrosives & abrasives

- Back pump out vanes minimise seal chamber pressure

Applications

Application:

This pump is ideal for handling highly corrosive liquids at elevated temperatures, such as chlorinated solvents, aromatic organic compounds, alcohols, ejector systems, and more.

Design:

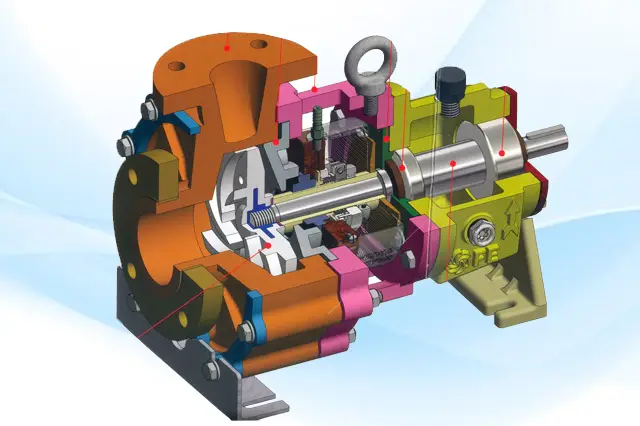

Engineered for improved efficiency and enhanced performance, this horizontal back pull-out process pump features a non-metallic lining.

Lining Process:

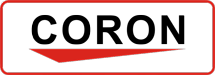

A state-of-the-art high-pressure lining technique, free from adhesive bonding, ensures a defect-free lining with no cavities or voids.

Mechanical Bonding:

Unique dovetail grooves in the lining areas of metal components provide a secure mechanical grip.

Full Protection:

The lining covers all wetted parts for maximum chemical resistance.

Material Options:

Various lining materials are available to handle almost any fluid within a temperature range of -100°C to +230°C.

Shaft Sleeves:

Shaft sleeves are available in high-alumina ceramic, Hastelloy, titanium, and silicon carbide.

Operating Speeds:

Both 1440 RPM and 2900 RPM models are available.

Sealing Options:

The models support a wide range of shaft sealing options, including gland packing and mechanical seals.

Availability:

Ready stock is available at highly competitive prices to meet urgent and budget-conscious requirements.

Severe Corrosive Services

- Hydrochloric Acid

- Hydrofluoric Acid

- Ferric Chloride

- Pickling Acid

- Plating Acid

- Plating Solutions

- Chlorinated Hydrocarbons

- Sodium Hypochlorite

- Chlorine Dioxide