AODD Metallic & Non-metallic Pumps

At Coron Enterprise, we specialize in high-performance AODD (Air-Operated Double Diaphragm) pumps, available in both metallic and non-metallic options. Our comprehensive range is designed to handle a variety of applications, offering superior durability, chemical resistance, and consistent flow rates.

We offer AODD pumps in a wide selection of sizes and configurations to meet your specific pumping needs. Whether you’re looking for pumps for chemical processing, water treatment, or industrial fluid transfer, Coron Enterprise delivers reliable, efficient, and easy-to-maintain solutions.

With a proven track record of performance, fast delivery, and customer-focused service, Coron Enterprise is your trusted partner for quality AODD pump solutions.

Models

SIZE | 0.5” | 1” | 1.5” | 2” | 3” |

MOC | PP | PP | PP | PP | PP |

PVDF | PVDF | PVDF | PVDF | PVDF | |

SS-316 | SS-316 | SS-316 | SS-316 | SS-316 | |

ETFE | ETFE | ETFE | ETFE | ETFE | |

PTFE | PTFE | PTFE | PTFE | PTFE |

Note: Other sizes and MOC are available on request.

What is an air-operated double-diaphragm (AODD) pump?

An air-operated double-diaphragm (AODD) pump is a type of positive displacement (PD) pump. It features two pumping chambers that are alternately filled and emptied by the movement of flexible diaphragms. Air chambers on opposite sides of the diaphragms alternately supply and vent compressed air, generating the pumping action.

AODD pumps are commonly used for transfer applications and are capable of handling a wide range of fluids, including sludges, slurries, abrasive materials, and shear-sensitive liquids. While these pumps are known for their robustness, reliability, and ease of maintenance, they can be noisy, susceptible to icing, and are generally limited to low-pressure applications.

How does an AODD pump work?

An AODD (air-operated double diaphragm) pump moves fluid by using two flexible diaphragms that push and pull back and forth on a shared shaft. While a motor can directly drive diaphragm pumps, AODD pumps rely on compressed air. A sophisticated air distribution system alternately directs compressed air to two air chambers located on opposite sides of the diaphragms.

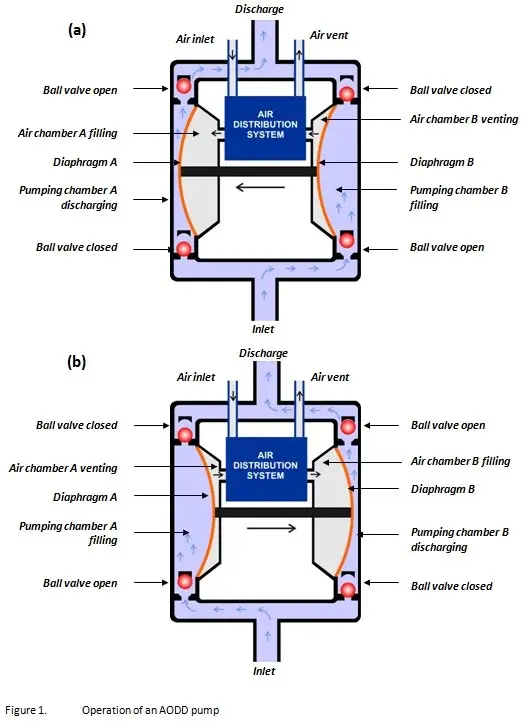

Figure 1 shows a complete operating cycle of an AODD pump:

The compressed air control system directs air into air chamber A.

The shaft moves to the left. This movement increases the volume of pumping chamber B while simultaneously decreasing the volume of pumping chamber A (Figure 1a). Check valves on either side of the pumping chambers ensure one-way fluid flow—from inlet to discharge. As a result, fluid is drawn into chamber B from the inlet and discharged from chamber A.

As the shaft completes its stroke, the air distribution system vents air chamber A and redirects compressed air into air chamber B.

The shaft now moves to the right, decreasing the volume of chamber B and increasing the volume of chamber A (Figure 1b). This causes fluid to be discharged from chamber B and drawn into chamber A.

Once the stroke is complete, the air distribution system vents air chamber B. The cycle then repeats as compressed air is once again directed to air chamber A.

What are the main features and benefits of an AODD pump?

AODD (air-operated double-diaphragm) pumps are essentially leak-free. Since there are only stationary seals between the wetted parts and the external environment, leakage typically occurs only if one or both diaphragms fail. As part of routine maintenance, diaphragms should be replaced periodically according to the manufacturer’s recommendations. Compared to mechanically driven diaphragm pumps, AODD diaphragms experience less wear due to pressure balancing provided by the compressed air supply.

AODD pumps can handle a wide range of challenging fluids, including abrasive and highly viscous liquids, sludges, and slurries. Their gentle pumping action makes them particularly suitable for shear-sensitive fluids.

The pumps feature four internal check valves, usually of either the ball (or cone)/seat type or flap type:

- Ball valves provide a tighter seal and are less prone to wear. Because the ball can rotate during operation, wear is distributed more evenly, which increases service life.

- Flap valves handle fluids with larger entrained solids better, although they are more susceptible to fatigue at the flexing point due to their hinged design.

AODD pumps contain no internal seals or moving parts that require lubrication or cooling, allowing them to run dry indefinitely without damage. They are also self-priming and can achieve suction lifts of up to 8 meters in some cases.

Since they are powered by compressed air rather than electricity, AODD pumps are safe for use in hazardous areas. This also makes it possible to submerge the pump, provided the air vent remains above the liquid level.

What are the limitations of an AODD pump?

The performance and efficiency of an AODD (air-operated double-diaphragm) pump depend heavily on the quality and pressure of its compressed air supply. The air pressure must be equal to or greater than the pressure of the fluid being pumped, which typically limits AODD pumps to low-pressure applications (generally up to 120 psi).

Flow rate and pump speed are governed by the differential between the compressed air pressure and the pressure of the pumped fluid. Increasing the air pressure or reducing the fluid pressure increases the pumping speed. However, achieving a constant flow may require additional flow and pressure control systems.

The air distribution system powers and controls the pump. While it is generally simple, low-cost, and easy to maintain, in certain environments, it may be necessary to filter the expelled air to remove contaminants like oil.

A potential issue with some AODD pumps is icing, especially in systems with poorly designed air distribution. Continuous venting of air causes cooling and, in extreme cases, can lead to ice formation around the air vent or inside the system.

This issue can be minimized by

- Avoiding air path constrictions

- Using low-humidity compressed air

- Installing an air-line heater

- Lowering the air supply pressure

The cyclic diaphragm action produces pulsations in the discharge flow, where fluid accelerates during compression and slows during suction. Although using two diaphragms out of phase reduces this pulsing effect, additional damping or smoothing devices are often required downstream. Pulsing can cause vibrations in the discharge piping, which may lead to loosened fittings or leakage. A flexible connection at the pump outlet helps minimize such issues.

AODD pumps can be loud due to the pulsing action’s vibrations and the air venting through the valves. This airborne noise can be reduced by installing a muffler on the air vent line.

What are the Main Applications for AODD Pumps?

While motor-driven diaphragm pumps are commonly used for precise metering, dosing, or dispensing applications, AODD pumps serve as versatile workhorse devices, primarily used for fluid transfer. They are cost-effective, robust, and highly reliable, making them ideal for a wide range of industrial applications. AODD pumps can run dry without damage and are well-suited for handling dirty or contaminated liquids, sludges, slurries, and abrasive or viscous fluids.

The following table lists some typical applications of AODD pumps:

| · Dewatering above and below ground sites and quarries · Transferring abrasive slurries and sludge mixtures · Dosing reagents · Transferring solvents for separating minerals from ore · Transferring fuels for vehicles and equipment |

| · Transferring, dispensing and dosing paint, ink and dyes · Feed pump for spray guns · Flush/clean paint lines with solvents |

| · Ceramic slips · Day tank transfer · Filling moulds · Circulating ceramic slurry · Waste water transfer |

| · Loading and unloading tankers, totes and barrels · Portable utility pump · Batching/dosing chemicals |

| · Replenishing chemicals in plating and metal finishing tanks · Agitation of cleaning solutions · Circulation of liquid to avoid sedimentation · Filtration (when critical purification is required for high quality parts) · Offloading corrosive, solid laden waste |

| · Printing inks · Glues · Kaolin clay · Bulk transfer · Resins · Dispersions |

| · Settling pond transfer · Oils and glycol transfer · Sumps · Filter press · Bulk transfer |

| · Transferring solid laden media · Filter press · Sumps

|